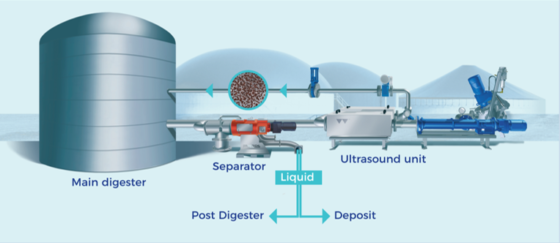

In cooperation with the company Paulmichl, Weber Entec has developed the “SepaSound” process, which was specially designed to increase efficiency in biogas plants. This technology enables comprehensive ultrasonic disintegration of biomass by first separating the digestate from the post-digester using a solid-liquid separator. The liquid phase is disposed of, while the solids are returned to the main digester via the ultrasonic disintegration. Ultrasonic disintegration causes cell disruption, which increases the substrate surface area and accelerates biological activity. This leads to a higher gas yield with the same retention time in the digester.

Biogas plants that use large quantities of liquid manure benefit particularly from this technology. It allows for precise adjustment of the solids content in the digester, which contributes to increased efficiency. In addition to the increased biogas yield, the viscosity of the substrate is significantly reduced, which improves the energy efficiency of biogas plants. This viscosity reduction facilitates the operation of pumps and agitators and contributes significantly to the reduction of energy consumption.

SepaSound – the process

The innovative SepaSound technology can be easily integrated into existing biogas plants as a “plug & play” module. This compact system consists of a 20-foot container with the separator mounted on the roof. After separation, the liquid phase is disposed of, while the separated solid phase is transferred to an agitated buffer tank. The substrate is then continuously pumped back through the ultrasonic disintegration system into the main digester. Ultrasonic disintegration improves the flow properties and ensures efficient cell disruption and improved utilization of the substrate in the digester.