substrate savings

Jetzt Kontakt aufnehmen

Repowering at Biogas & Waste water treatment plants

… and again another ultrasound disintegration plant was installed!

Jühnde is the first bioenergy village in Germany and even worldwide. Heat and power demand is produced by a renewable energy biogas plant as well with photovoltaik technology.

From 27 to 29 January Weber Entec presented the innovative products and developments on the Annual Conference and Trade Fair in Bremen.

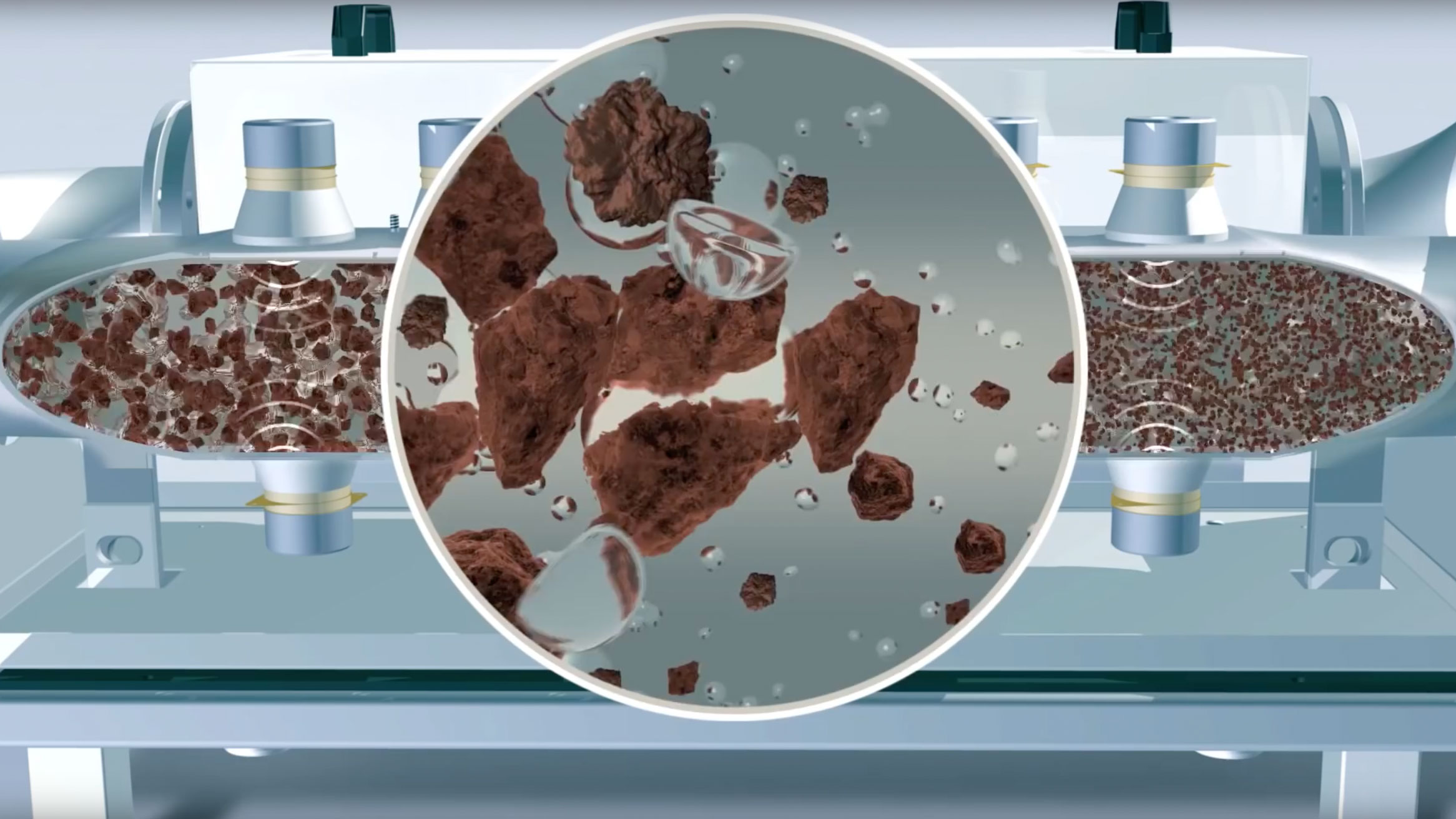

Our partner United Engineers in Singapore won a tender for the Ulu Pandan waste water treatment plant, for substrate digestion of the surplus sludge. A plant with 16 BioPush ultrasonic reactors was installed. This brings Weber Entec’s disintegration technology into use in Singapore for the first time.

Dal 2011 Weber Entec distribuisce in esclusiva in Germania, Austria, Svizzera e Paesi Bassi il sistema AMPTS II sviluppato dal produttore svedese Bioprocess Control.